When we last met I had just finished my first successful screen and was starting on my second. Like I said, the second time was a lot smoother but no where near as user-friendly and the more traditional method I already know.

Once my screens were burned and dried, I got to printing. Luckily I was forewarned about the fact that the screens shift around a lot during printing so I used the packing tape used to block off the edges of the screen to tape the screen into the machine. I then prepared my platen for my fabric.

Ah, the platen. . . the thing that holds your work in place as you print. It should be sticky but not too sticky. You should be able to remove the printed material without distorting or tearing it. Apparently the Yudu folks didn't get that memo because this thing was so sticky that I couldn't even remove the piece of wax paper I'd put down as a guide!

So annoying and frustrating. Most of my print time was spent trying to de-tacky the platen. Did they not even DO any product testing? Apparently they sell extra adhesive sheets for the platen ($7.99 for 2 cha-ching!) so you can have it way too sticky and fabric distorting all the time. Yea.

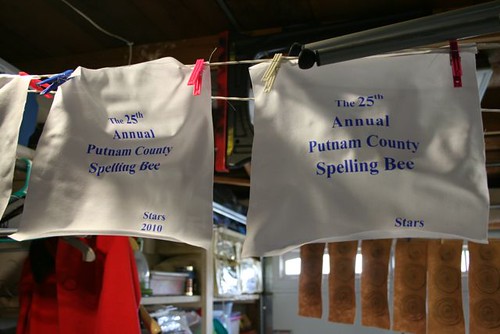

Here's the distorted fabric after printing and removal:

It took a lot of steam and stretching to reshape the fabric after printing.

So, the platen sucks. But still, we soldier on. Printing! As you can see the print on the white fabric is crisp and clear, but it took several passes to get it that way. I've only had that happen in a traditional set up when using a super porous fabric like felt. With a smooth cotton (like the one I used on this project) it should really only take one pass, but still it's a nice print.

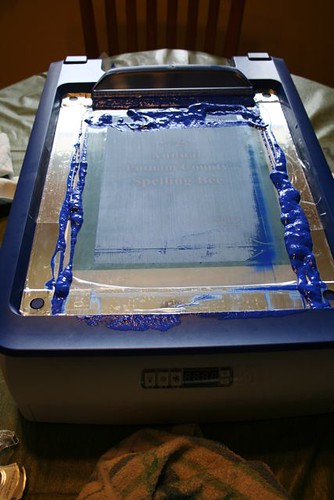

My biggest gripe is the mess. One of the many reasons I wanted the Yudu is that I liked the idea that I could use it indoors and that it seemed rather mess-free for screenprinting. But this is SO not the case. Now, I must admit, I did not use the Yudu ink. Maybe that would make a difference but I doubt it. The ink went everywhere as I printed and there was no easy way to scoop up the ink for re-use after a pull of the squeegee. As for the squeegee, there's no place to put it when you're not using it! When I print in my garage, I can rest the squeegee in the screen frame when I lift the frame up to remove the printed work. On the Yudu, this is not possible. When I tried to rest it there it would fall into the ink or worse off of the machine getting ink all over the place. I finally had to lay out some plastic along the side of my work area so that I could put the squeegee there when not in use.

Messy. Notice the ink all over the machine.

The next thing I printed with the machine didn't go much better. I decided to print opaque white on red cotton flannel. Even though I was using a super opaque ink I was still unable to get a crisp opaque print from the Yudu no matter how many times I pulled the squeegee. Ultimately I just touched up the white by hand. Really, Yudu, what's the point?

I was still able to use the fabric I printed for my final project and it still turned out really nice. See. . .

But I feel the Yudu was more hindrance than help and that I could have finished the printing a lot faster and better with my low-fi garage set-up.

Still, looking on the bright side, it is a really nice lightbox.

Hearts and puppies,

erika

2 comments:

L.O.V.E. the plush dictionaries!!

also, the Yudu sounds like a fail ;o( which is so sad b/c it could have been so good... sigh...

Thanks!

Yeah, it just feels like they didn't want to make the best printing machine, more that they just wanted to make the most money possible.

Post a Comment